Ball bearings

Ball bearings are small but critically important components that ensure the uninterrupted operation of machinery. Due to their affordability, easy installation, and simple maintenance, they are most commonly chosen for standard conditions. Low friction and smooth rotation deliver efficiency and reliability in every movement, allowing equipment to perform at its best without unnecessary costs.

For companies looking to buy ball bearings, this type remains one of the most practical and cost-effective solutions for a wide range of industrial applications.

Size range

NTE offers the option to order ball bearings online in an extensive range of sizes, facilitating the selection of the appropriate option for various equipment:

- Bore diameter: from 10 to 1400 mm

- Outside diameter: from 26 to 1700 mm

- Bearing width: from 8 to 176 mm.

The full-size range is available in the NTE technical catalogue.

Specific dimensions depend on the type of bearing and are discussed individually when placing an order.

Design and operating principle

NTE ball bearings are typically delivered ready for installation and do not require disassembly before use. This results in time savings, simplified maintenance, and ensures consistent operational performance.

They consist of an outer and inner ring, and a ball cage. Such a design ensures smooth, vibration-free performance, transmission of radial and moderate axial loads, and allows reliable performance at elevated rotational speeds.

Available cage options for different operating requirements include:

- Pressed steel cage – standard for most applications;

- Polyamide and thermoplastic cages – for low noise operation;

- Machined brass cage – suitable for high speeds and heavy loads;

- Textolite cage – designed for high-speed assemblies where low moment of inertia is required.

To match specific operating conditions, bearings are available in the following configurations:

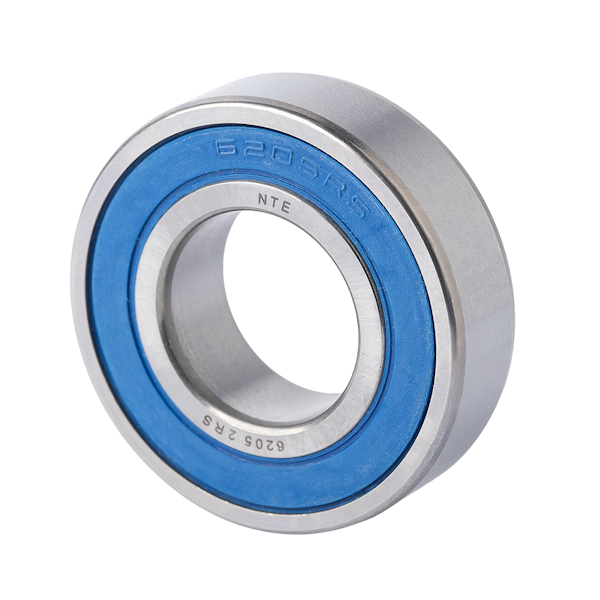

- Open design – for assemblies with external lubrication;

- RS seals – for protection against dust and dirt;

- ZZ metal shields – optimal for enclosed systems;

- UG and WL grooves – for additional sealing elements;

- N groove with NR snap ring – for axial fixation.

Technical specifications

- Maximum rotational speed – depends on the type and size of the bearing; select the bearing type.

- Operating temperature range – from –30°C to +120°C.

- Basic dynamic load rating – depends on the type and size of the bearing; select the bearing type.

Current values for speed, loads, and temperatures are shown in the NTE technical parameters table.

Industrial advantages

The key technical advantage that makes many customers choose ball bearings is the low friction between moving parts when transmitting loads. As a result, mechanisms run smoothly, operate stably, and have a long service life.

Additional benefits include:

- Minimal vibration, which is especially critical for precision mechanisms.

- Versatile installation due to a wide range of designs.

- Increased stiffness, especially in double-row configurations.

- Operability in various conditions – from limited installation spaces to high speeds.

Sealing options (RS, 2RS, ZZ, 2ZR) protect components from dust, dirt, and oil, while the stainless steel bearings are resistant to water, chemicals, and corrosion. The combination of these factors prolongs service life and enables scheduled maintenance rather than emergency repairs.

Fields of application

NTE ball bearings are widely used across multiple industries, including:

- Mechanical engineering – machine tools, industrial equipment, gearboxes, conveyors.

- Power generation – electric motors, generators, turbines, and pumping systems.

- Agricultural machinery – tractors, combines, harvesters, processing machines.

- Construction machinery – rollers, compactors, excavators, loaders.

- Food industry – mixers, conveyors, dosing equipment, mills

Our specialists will help you select the most cost-effective solution for your specific application, including options available through our ball bearings online store, ensuring quiet and uninterrupted operation.

Ball bearing types

Radial bearings are the most common and versatile, often chosen for standard assemblies. In addition, the catalogue includes:

- Miniature bearings – for precise and compact devices where space savings are important.

- Self-aligning bearings – compensate for shaft misalignment without manual adjustment.

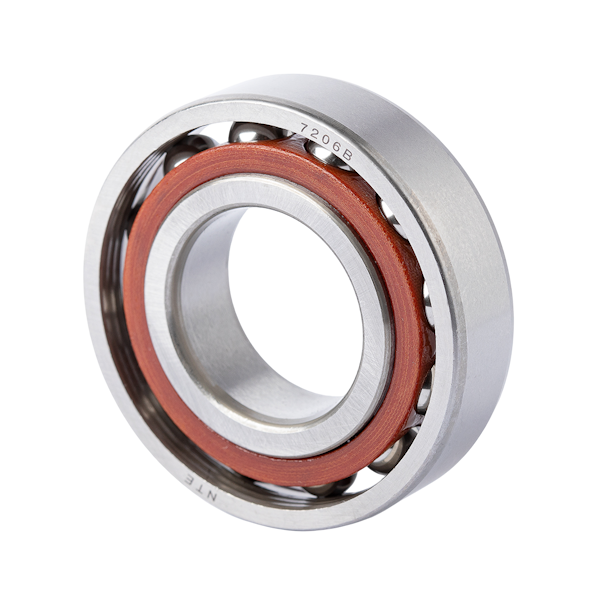

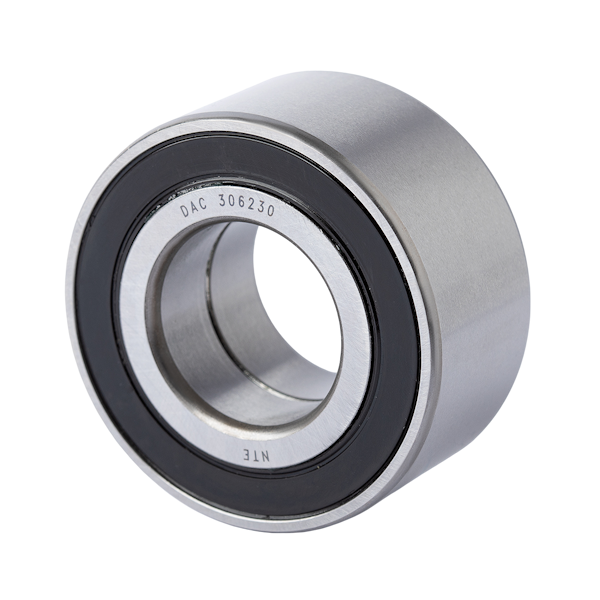

- Radial-thrust bearings – suitable for assemblies with combined loads, saving space and simplifying the design.

- Four-point contact bearings – for high-precision and high-speed mechanisms under simultaneous radial and axial loads.

- Thrust bearings – reliable shaft fixation along the axis, protection of the mechanism from displacement, and increased accuracy of operation.

Why choose NTE

- Stable supply – reduced waiting times.

- Quality assurance – certified products and multi-stage inspection.

- Flexible terms of cooperation – the option to buy bearings wholesale, discounts, and tailored offers.

- Extensive product range – multiple sizes and designs available.

Simple yet essential, ball bearings determine the efficiency and durability of mechanisms. Contact NTE distributors to select the optimal solutions for your industry, equipment type, and budget.

Take advantage of favorable terms and support – become an NTE distributor today!

We offer bearings compliant with international quality standards. NTE products are manufactured at certified facilities, undergo strict inspection, and combine durability, precision, and stable performance. Their high quality is confirmed by experience in automotive, electrical engineering, machine building, and metallurgical industries.

For distributors we offer:

- Technical support

- Certificates & documentation

- Special prices

- Convenient cooperation terms

- Ongoing support

- Easy interaction