Radial ball bearings

NTE radial ball bearings are designed to ensure smooth, precise, and trouble-free operation of your mechanisms. They can withstand high radial and partial axial loads, minimizing friction and heat generation for maximum service life. These components are easy to integrate into a wide range of industrial applications. Their reliability provides long-lasting and stable operation of equipment when selected and operated correctly.

Size range

The portfolio includes a full range of dimensional variations, allowing you to order radial ball bearings for small and medium mechanisms as well as for heavy-duty industrial equipment:

- Bore diameter: from 10 to 1400 mm

- Outside diameter: from 26 to 1700 mm

- Bearing width: from 8 to 132 mm

Such a wide selection enables not only the design of new equipment in line with modern requirements and loads, but also the effective maintenance and modernization of existing systems.

The full-size range is available in the NTE technical catalogue.

Design and jperating principle

The outer and inner rings of NTE bearings are processed to ensure smooth and stable ball movement, while high-quality bearing steel provides strength, wear resistance, and load capacity. High-quality material, optimal geometry of elements, and a contact angle of 15°-25° reduce friction and ensure smooth rotation, allowing mechanisms to operate accurately and without failure.

Additional operational reliability is achieved through cage options:

- Stamped cages – minimal friction and stability at moderate speeds.

- Polyamide cages – lightweight, quiet, and wear-resistant, ideal for high-speed assemblies.

- Brass cages – for large bearings or assemblies with increased loads.

Cages maintain proper ball spacing and ensure even load distribution. Their material choice significantly affects the radial bearings price.

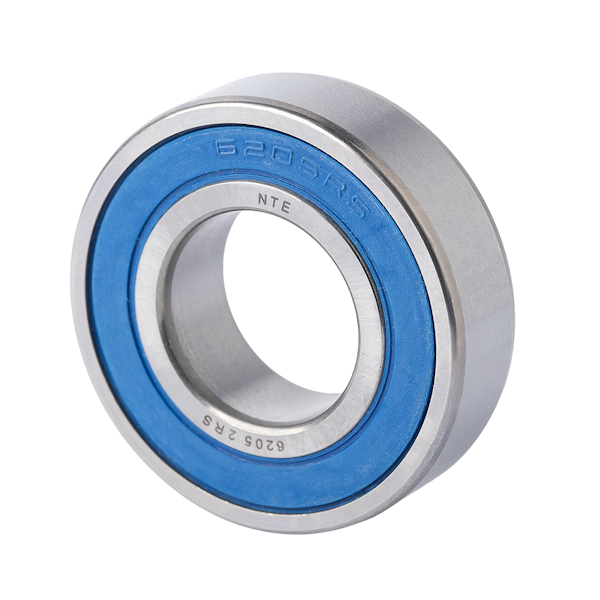

For operation in aggressive environments – such as dust, water, or chemicals – we suggest bearings with seals or washers on one or both sides. They extend service life and reduce maintenance costs.

Technical specifications

In industrial applications, bearing overheating can cause equipment to shut down. Therefore, NTE offers options for different operating conditions and loads:

- Maximum rotational speed – up to 130,000 rpm (depending on bearing size, lubricant type, and operating conditions).

- Operating temperature range – typical sealed bearings usually operate in the standard industrial range of -30 to +120 °C.

- Basic dynamic load rating – from 0.54 kN for small bearings to 1,210 kN for large bearings.

Current values for speed, loads, and temperatures are shown in the NTE technical parameters table.

Industrial advantages

NTE radial ball bearings are capable of withstanding not only normal radial loads, but also axial forces up to 50% of their basic load capacity. This ensures stable and failure-free operation even under shaft misalignment or combined load conditions.

These characteristics provide ball radial bearings with the following advantages:

- Versatility of application – a wide range of designs suitable for various mechanisms and operating environments.

- Smooth and efficient operation – low noise and vibration, smooth rotation, reduced heat generation, and increased equipment productivity.

- Ease of installation and maintenance – standardized dimensions allow replacement or upgrades without modifying equipment design.

Due to the versatility of the design, this type is relevant for both mass production and maintenance. Therefore, it is quite reasonable to buy radial ball bearings wholesale – without the risk of excess inventory remaining unused.

Fields of application

They are used almost everywhere where there are rotating assemblies and mechanisms:

- Electric motors, gearboxes, and drive systems.

- Pumps and compressors.

- Agricultural machinery (harvesters, balers, conveyors).

- Machine tools and spindle units.

- Conveyor lines and transport systems.

- Ventilation and air-conditioning equipment.

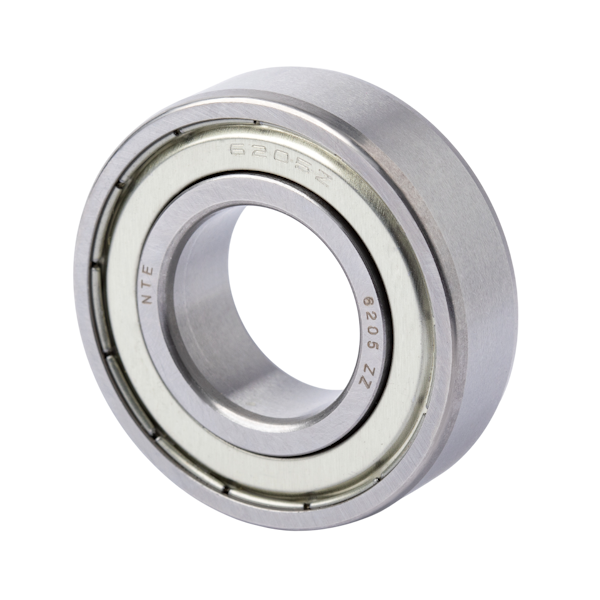

Radial ball bearings types

Many series are manufactured in higher precision classes – P6, P5, and sometimes P4 – for precision mechanisms. This guarantees minimal clearance, smooth running, and positioning accuracy. However, bearing performance also depends on the specific type:

- Single-row open bearings – lighter and quieter due to minimal friction; ideal for clean environments where precision and smooth movement are important.

- Single-row sealed bearings – supplied fully lubricated, require no maintenance throughout their service life, and perform well in contaminated environments.

- Double-row bearings – double strength for mechanisms: more balls mean greater resistance to loads and maximum stability even with shaft misalignment up to 2.5°.

For special designs, including miniature bearings, please contact our specialists for consultation.

Why choose NTE

- Stable supply – reduced waiting times.

- Quality assurance – certified products and multi-stage inspection.

- Flexible terms of cooperation – the option to buy bearings wholesale, discounts, and tailored offers.

- Extensive product range – multiple sizes and designs available.

There are many reasons to buy radial ball bearings for industrial applications, but the key advantage is their proven reliability and versatility. That means less downtime and fewer repairs, allowing for a more focused and productive operation. Choose the NTE solution that fits your budget and production requirements, and keep your equipment running on schedule!

Take advantage of favorable terms and support - become an NTE distributor today!

We offer bearings compliant with international quality standards. NTE products are manufactured at certified facilities, undergo strict inspection, and combine durability, precision, and stable performance. Their high quality is confirmed by experience in automotive, electrical engineering, machine building, and metallurgical industries.

What we offer distributors:

- Professional technical support

- Certificates & documentation

- Special purchase prices

- Convenient terms of cooperation

- Ongoing support

- Easy interaction

Contact us by email – become an NTE partner today!