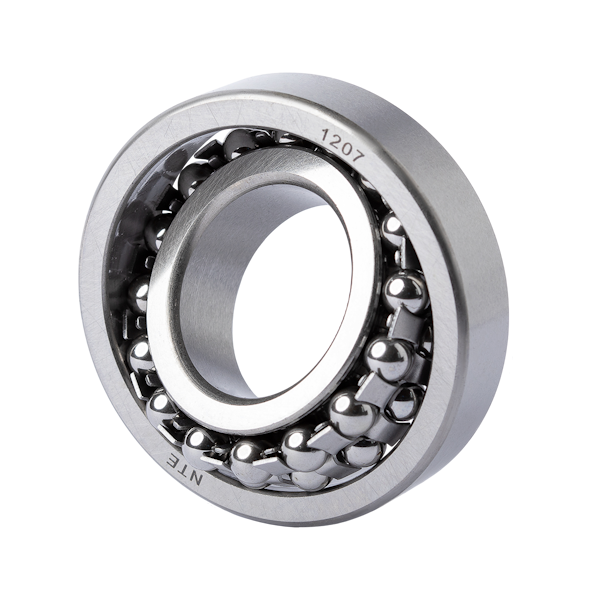

Self-propelled cultivator bearings

Radial double-row spherical ball bearings are meant to handle radial and small axial loads in both directions. They are self-aligning and capable of operating properly with shaft misalignment relative to the housing of up to 2.5°, while sealed versions allow up to 1.5°. NTE models like these ensure smooth operation and protect assemblies from premature wear.

Size range

Catalog of self-propelled cultivators by NTE features a wide size range, offering fewer limitations and more possibilities for your company’s technical solutions:

- Bore diameter: from 5 to 130 mm

- Outside diameter: from 19 to 240 mm

- Bearing width: from 6 to 80 mm.

The full-size range is available in the NTE technical catalogue.

Design and operating principle

NTE self-propelled cultivator bearings include two rows of balls and a spherical raceway on the outer ring. Such a design is essential in various mechanisms that may experience significant misalignment of bearing seats, as well as in cases where shaft or axle deflection is unavoidable – such as in textile machine transmissions, industrial fans, agricultural machinery, etc. As a result, the bearings run smoothly, quietly, and stably, with reduced vibration, less wear, and a longer service life for all equipment.

You can order self-propelled cultivator bearings in two configurations:

- Open – for systems with regular external lubrication and high operating speeds.

- Sealed (2RS) – reliably protects the bearing from dust and moisture, retaining lubricant throughout its service life.

Correct cage selection ensures assembly safety and longevity:

- Steel – for standard and increased loads, highly reliable.

- Brass – optimal for impact and fluctuating loads; guarantees stability in harsh conditions.

- Polyamide – for high speeds and quiet operation of equipment.

Technical specifications

The combination of high speed, load capacity, and misalignment compensation results in fewer downtimes, lower operating costs, and predictable technological processes:

- Maximum rotational speed: Consistent lubrication – up to 30,000 rpm; liquid lubrication – up to 45,000 rpm (depending on operating conditions).

- Operating temperature range: –30…+80 °C (sealed models) and up to 100 °C for open designs.

- Basic dynamic load rating: up to 163 kN.

Current values for speed, loads, and temperatures are shown in the NTE technical parameters table.

Industrial аdvantages

If you are looking to purchase wholesale self-propelled cultivator bearings, consider their numerous advantages, such as:

- Stability under challenging conditions. Misalignment compensation reduces uneven load on the assembly and prevents emergency stoppages.

- High efficiency even at high speeds. Low friction ensures smooth motion without overheating, enhancing equipment productivity.

- Minimal maintenance costs. Sealed models require no re-lubrication, while other versions need minimal lubrication, reducing service costs and extending maintenance intervals.

- Quiet, stable, and long-lasting operation. Reduced vibration prolongs the life of the bearing, housing, shafts, belts, and other connected components.

Fields of application

NTE bearings have proven effective across key industrial sectors:

- Agriculture – seeders, harvesters, conveyors, feed distributors, and other farm machinery.

- Food industry – production, processing, and packaging equipment; mostly sealed models are used.

- Industrial HVAC equipment – climate control units, air conditioners, fans, blowers.

- Metalworking – machine tools, roller tables, assemblies with vibration and misaligned shafts.

- Conveyor systems and roller transporters – logistics, production, and sorting lines.

- Wood and paper industry – equipment exposed to shaft thermal deformation, cutting, and feeding mechanisms.

Self-propelled cultivator bearings types

The NTE catalog includes two main designs:

- Cylindrical bore – the most common option; easy mounting, high centering accuracy, installation without adapter sleeves.

- Tapered bore – for high-load and high-vibration applications; mounted with H-type adapter sleeves, allowing precise preload adjustment and secure fit on smooth shafts.

Why choose NTE

- Stable supply – reduced waiting times.

- Quality assurance – certified products and multi-stage inspection.

- Flexible terms of cooperation – the option to buy bearings wholesale, discounts, and tailored offers.

- Extensive product range – multiple sizes and designs available.

For enterprises seeking reliability and predictability, the decision to buy self-propelled cultivator bearings is practical and cost-effective. Choose stability with NTE!

Want to purchase?

Our official distributors

Take advantage of favorable terms and support - become an NTE distributor today!

We offer bearings compliant with international quality standards. NTE products are manufactured at certified facilities, undergo strict inspection, and combine durability, precision, and stable performance. Their high quality is confirmed by experience in automotive, electrical engineering, machine building, and metallurgical industries.

What we offer distributors:

- Professional technical support

- Certificates & documentation

- Special purchase prices

- Convenient terms of cooperation

- Ongoing support

- Easy interaction

Contact us by email – become an NTE partner today!