Bearing units and split bearing housings

Incorrect initial installation of the bearing or shaft misalignment can result in premature failure of the mechanisms. NTE bearing units are supplied fully assembled and ensure fast installation and accurate self-alignment. The split housing provides flexibility: components can be repaired without dismantling adjacent elements.

Size range

A wide selection makes it possible to order split bearing housings or complete bearing units that precisely match your installation conditions:

- Housing sizes: UCF, UCFC,UCFL, UCP, UCPA, UCT, UKF, UKFC, UKFL, UKP, UKT, SN, SNU

- Shaft diameter range: 12...95 mm

- Housing dimensions: see catalog

The full-size range is available in the NTE technical catalogue.

Design and operating principle

If an adaptive and service-friendly design is required, we recommend to buy split bearing housings of the SN and SNU types, which can be configured according to specific technical requirements.

Key components of the complete bearing unit:

- Housing – standard material is gray cast iron. Versions made of malleable cast iron, steel, stainless steel, or plastic are also available. Depends on operating conditions.

- Spherical outer ring of the bearing – a ring with a spherical outer surface that self-aligns inside the housing relative to the shaft.

- Lubricant and grease nipple – factory lubricant with a built-in channel for its supply.

- Insert bearing – a ball rolling element designed to handle radial and limited axial loads.

- Seals – protection against dust and moisture for operation in harsh conditions. Standard design – with single-lip seal and protective washer, reinforced seal designs are also available for particularly harsh conditions.

- Steel cage – maintains uniform ball spacing and ensures even load distribution.

NTE also supplies split bearing housings wholesale without insert bearings, allowing the assembly to be configured to your technical requirements.

Technical specifications

Specific values depend on the type of insert bearing and operating conditions:

- Maximum rotational speed – assemblies are selected for specific operating conditions: from medium speeds to high-speed systems.

- Operating temperature range – from -40°C to 120°C.

- Basic dynamic load rating – designed for medium and high loads.

Current values for speed, loads, and temperatures are shown in the NTE technical parameters table.

Industrial advantages

Mass production ensures a competitive split bearing housings price for reinforced cast-iron housings capable of handling increased loads. In addition to cost efficiency, NTE ready-to-install units offer multiple technical benefits:

- Self-centering in the housing – spherical mounting compensates for mounting misalignments without additional shaft alignment.

- Rigid mounting to the frame – the housing provides secure fixation and stable geometry under load.

- Integrated seal – bearing protection is already provided by the design and does not require additional elements.

- Convenient maintenance – lubrication is possible without shaft removal.

- Quick replacement of the insert bearing – in case of wear, only the insert is replaced, not the entire assembly, which reduces operating costs.

These technical advantages save time and optimize maintenance costs, reduce downtime, and increase the reliability of production processes.

Fields of application

NTE manufactures and supplies split bearing housings and complete bearing units for a wide range of industries:

- Mechanical engineering – belt and roller conveyors, material handling systems, drive mechanisms, and auxiliary equipment.

- Agriculture – harvesters and headers, cultivators, seeders, tillage machinery, grain conveyors, and augers.

- Food and packaging industry – conveyor lines, filling and packaging equipment, sorting and washing machines.

- Ventilation and climate control systems – industrial fans, air handling and exhaust units.

- Construction and road equipment – concrete mixers, crushing and screening plants, mobile conveyors.

Bearing units type

The split bearing housings price is generally competitive, selection depends not only on cost but also on the unit type:

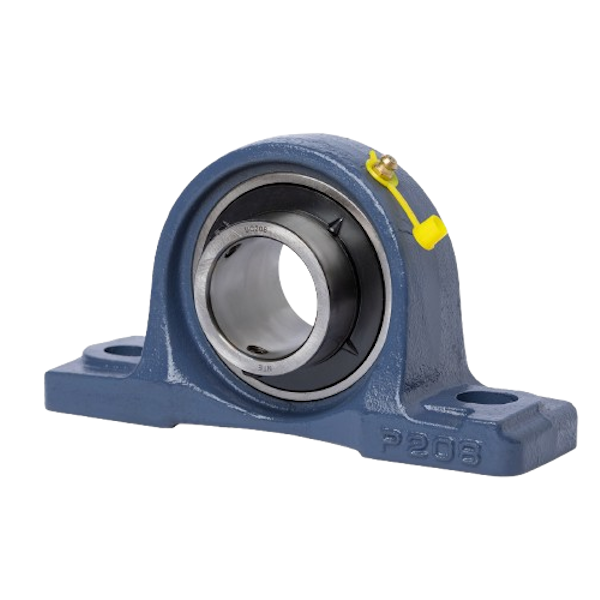

- Pillow block units. This is the most common option for quick installation on a horizontal support surface. They ensure stable shaft fixation and easy maintenance. For standard conditions – UCP; for start-stop operation – UCPA; for precise centering – UKP with a tapered bore.

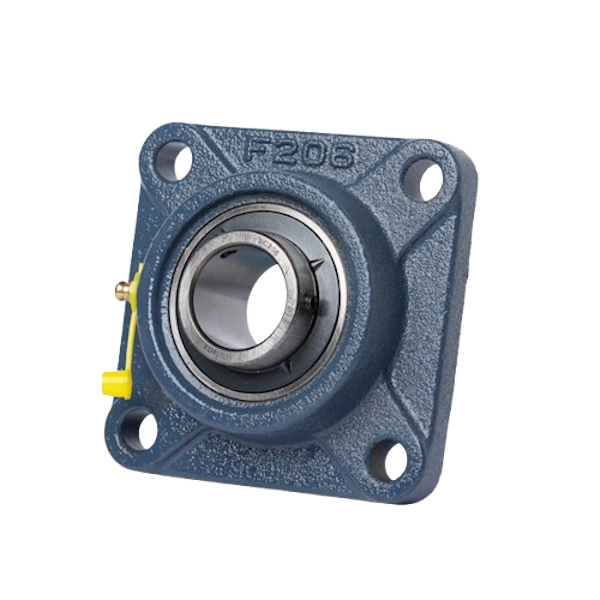

- Flange units – are designed for mounting on vertical or side surfaces. They provide vibration resistance and high installation accuracy. Square, oval, and round flange designs are available for various structural requirements.

- Take-up units (UCT/UKT) – designed to compensate for belt and chain tension, reducing drive wear.

NTE supplies split bearing housings wholesale, providing additional economic benefits to the consumer.

Why сhoose NTE

- Stable supply – reduced waiting times.

- Quality assurance – certified products and multi-stage inspection.

- Flexible terms of cooperation – the option to buy bearings wholesale, discounts, and tailored offers.

- Extensive product range – multiple sizes and designs available.

Efficient equipment operation starts with the right NTE components. Simplify maintenance and plan production with a trusted split bearing housings supplier!

Want to purchase?

Want to purchase?

Our official distributors

Take advantage of favorable terms and support - become an NTE distributor today!

We offer bearings compliant with international quality standards. NTE products are manufactured at certified facilities, undergo strict inspection, and combine durability, precision, and stable performance. Their high quality is confirmed by experience in automotive, electrical engineering, machine building, and metallurgical industries.

What we offer distributors:

- Professional technical support

- Certificates & documentation

- Special purchase prices

- Convenient terms of cooperation

- Ongoing support

- Easy interaction

Contact us by email – become an NTE partner today!