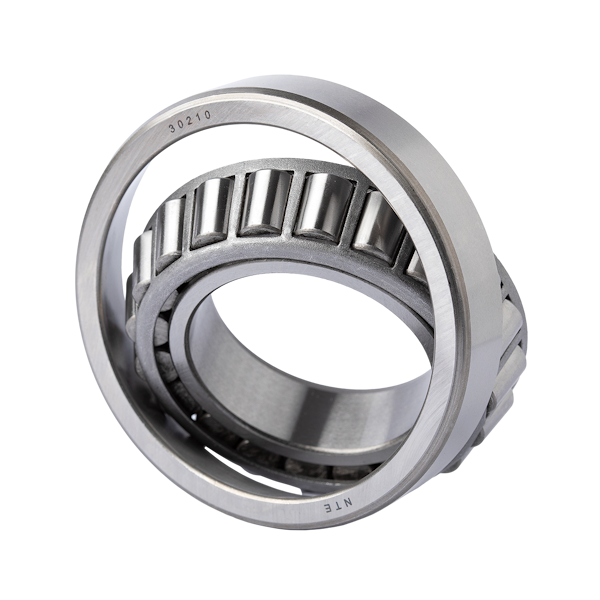

Roller bearings

Equipment downtime due to worn bearings is costly and disruptive to production schedules. NTE roller bearings ensure reliable operation even under high loads, reducing downtime and maintenance costs.

Size range

NTE offers roller bearings for sale in a wide variety of sizes, ensuring compatibility with different assemblies and units:

- Bore diameter: from 10 to 1600 mm

- Outside diameter: from 22 to 1280 mm

- Bearing width: from 11 to 408 mm

The full-size range is available in the NTE technical catalogue.

Design and оperating principle

NTE bearings are made of high-quality chromium steel or case-hardened steel, providing high hardness, wear resistance, and durability even under intensive use.

Main design elements:

- Rollers: high precision, with optimal contact area with the raceways. These effectively distribute heavy loads and reduce maintenance costs.

- Rings (inner and/or outer): high-quality machining of the raceways ensures stable roller movement, minimal friction, and a long bearing life even under heavy loads.

- Cages: made of steel, non-ferrous metals, or polymers; they maintain uniform roller spacing and prevent friction between rolling elements.

- Seals (optional): rubber or polymer seals protect against dust, dirt, and lubricant leakage.

Technical specifications

The reliability and durability of bearings is determined by precise technical parameters:

- Maximum rotational speed – up to 52,000 rpm (depending on size, contact angle, and other factors).

- Operating temperature range: typically from −30°C to +120°C, but can be higher with special lubricants.

- Basic dynamic load rating – up to 331 kN (allows the bearing to operate in power units at peak loads).

Current values for speed, loads, and temperatures are shown in the NTE technical parameters table.

Industrial advantages

NTE roller bearings are manufactured in accordance with international and national standards (ISO, DIN, JIS), ensuring interchangeability and predictable service life.

Even non-standard series, such as NKI, are based on proven engineering solutions and are therefore widely used in industry. One can buy roller bearings, for example, when ball models cannot implement the necessary design or installation solutions.

Regardless of the standard, all roller bearings share common advantages:

- High load capacity – linear contact between rollers and raceways enables the bearing to withstand heavy loads.

- Resistance to peak loads – allows the bearing to operate safely under sudden load changes and frequent starts.

- Combined radial and axial load capability (for angular contact and tapered designs) – allows simultaneous absorption of different force types, which is critical for gearboxes, conveyors, and drive systems.

- Reduced friction – cage designs with long straight grooves ensures the correct position of the rollers, which reduces wear on parts and energy consumption.

Fields of application

Roller bearings are used in heavy industrial equipment and agricultural machinery to operate under high radial and combined loads:

- Metallurgy: rolling mills, conveyors, rollers, blast furnaces.

- Machine building: machine tools, production equipment, electric motors, gearboxes, industrial drives.

- Energy sector: turbines, generators, pumping and compressor equipment.

- Automotive industry: wheel bearings for heavy vehicles, transmissions, gear reducers, intermediate shafts.

- Agriculture: tractors, combine harvesters, conveyor drives, threshing mechanisms.

Roller bearings types

NTE offers roller bearings wholesale of all possible types for various tasks:

- Cylindrical roller bearings – for high radial loads and moderate speeds.

- Tapered roller bearings – handle radial and axial loads simultaneously; effective for angular loads.

- Thrust roller bearings – designed to handle significant axial loads and compensate for shaft misalignment.

- Needle roller bearings – compact, used in narrow mounting spaces; withstand high loads with a small cross-section.

- Spherical roller bearings – self-aligning bearings for high radial loads. They have fewer requirements for mounting accuracy.

The wide range of roller bearing types makes it easy to select the optimal solution for specific operating conditions and tasks.

Why choose NTE

- Stable supply – reduced waiting times.

- Quality assurance – certified products and multi-stage inspection.

- Flexible terms of cooperation – the option to buy bearings wholesale, discounts, and tailored offers.

- Extensive product range – multiple sizes and designs available.

These components address one of the main challenges in industrial equipment—component failure due to high loads. Therefore, choose roller bearings price directly from NTE manufacturer and ensure efficiency and long-term reliability of your machinery!

Take advantage of favorable terms and support - become an NTE distributor today!

We offer bearings compliant with international quality standards. NTE products are manufactured at certified facilities, undergo strict inspection, and combine durability, precision, and stable performance. Their high quality is confirmed by experience in automotive, electrical engineering, machine building, and metallurgical industries.

What we offer distributors:

- Professional technical support

- Certificates & documentation

- Special purchase prices

- Convenient terms of cooperation

- Ongoing support

- Easy interaction

Contact us by email – become an NTE partner today!