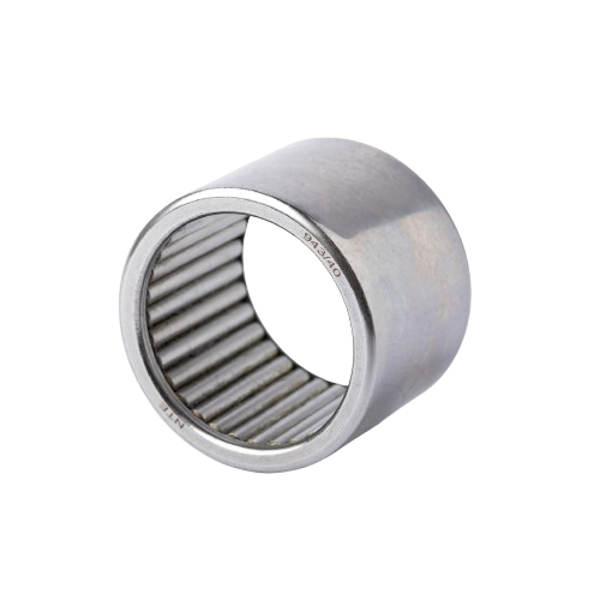

Needle roller bearingsr

When your mechanisms operate in intensive mode and with minimal tolerances, downtime always leads to additional costs. To ensure reliable performance even in confined installation spaces, NTE offers a wide range of needle roller bearings – compact, durable solutions capable of withstanding high radial loads.

Size range

Our needle bearings catalog covers a wide range of sizes:

- Bore diameter: from 10 to 360 mm

- Outside diameter: from 22 to 440 mm

- Bearing width: from 13 to 80 mm.

This allows easy selection of bearings for various designs – from compact assemblies to large-scale machinery.

The full-size range is available in the NTE technical catalogue.

Design and operating principle

Our products feature needle rollers made of high-carbon chromium steel, ensuring stable operation even in dynamic assemblies. A maximum contact area with the raceways combined with minimal roller thickness (3–5 mm) reduces friction, extends service life, and enhances overall equipment reliability.

We supply the following configurations:

- With cage: rollers, steel, brass, or polyamide cage, as well as inner and/or outer ring assembly. This ensures even load distribution and reduces friction.

- Without cage: rollers are in direct contact with the shaft and housing; a cost-effective solution for compact units.

Our bearings distribute loads evenly between the rings through the rotation of needle rollers. This guarantees stable operation at high speeds, minimal friction, and extended service life (typically 5–8 years under standard operating conditions), even in densely packed or space-restricted mechanisms.

Technical specifications

If you need reliable bearings, especially for dynamic assemblies, needle roller type bearings are the optimal choice due to the following parameters:

- Maximum rotational speed – up to ~28,000 rpm (depending on type and lubrication).

- Operating temperature range – from –30°C to +120°C (special designs – up to +140°C).

- Basic dynamic load rating – mainly up to 70 kN (the bearing series determines the exact value).

Current values for speed, loads, and temperatures are shown in the NTE technical parameters table.

Consult our specialists to buy needle bearings with the characteristics tailored to your equipment.

Industrial advantages

NTE bearings are designed to keep your mechanisms running for a long time without downtime. Compact size is only one of their advantages; additional benefits include:

- High load capacity – withstand heavy loads even with small roller diameters.

- Uniform load distribution – reduces wear and extends bearing service life.

- Minimal friction – reduces heating and increases the efficiency of mechanisms.

- Operational stability – reduced vibration, predictable lifespan, and fewer unplanned shutdowns.

- Low maintenance costs – especially with proper lubrication.

- Adaptability to operating conditions – suitable for confined spaces, high speeds, and varying temperatures.

What matters most is peace of mind and cost savings, given that NTE bearings undergo multi-level testing and comply with ISO/DIN standards. This implies trouble-free operation and reduced unplanned maintenance costs.

Fields of application

Practical experience confirms that NTE needle roller bearings are widely used in the following industries:

- Metallurgical industry – conveyor shafts, rolling mills, and roller lines.

- Automotive sector – gearboxes, differentials, starters, and generators in space-restricted assemblies.

- Agriculture – tractors, combine harvesters, conveyors, and soil cultivation equipment.

- Energy sector – compressors, pumps, and turbines.

- Pulp and paper industry – press mechanisms, conveyors, and auxiliary equipment.

Needle roller bearings types

We recommend selecting products based on the needs of your equipment:

- Without rings – the best choice for compact assemblies where space savings are important.

- With stamped outer ring – suitable when the housing cannot serve as a raceway; offers cost efficiency and operational reliability.

- With machined rings – recommended for cases where the shaft cannot be hardened or ground, provides stability under load.

- Special designs – self-aligning, combined, and thrust needle bearings; designed to compensate for shaft misalignment up to 3° and handle combined radial and axial loads. These solutions are recommended for demanding operating conditions.

Can’t decide on your choice? Our engineers will help you select and buy needle bearings for your operating conditions so that your mechanisms work for a long time without downtime.

Why choose NTE

- Stable supply – reduced waiting times.

- Quality assurance – certified products and multi-stage inspection.

- Flexible terms of cooperation – the option to buy bearings wholesale, discounts, and tailored offers.

- Extensive product range – multiple sizes and designs available.

Order needle bearings wholesale in the required quantities! The NTE team will select the optimal solution for your equipment type and calculated service life, helping your operations remain efficient and strictly on schedule.

Take advantage of favorable terms and support - become an NTE distributor today!

We offer bearings compliant with international quality standards. NTE products are manufactured at certified facilities, undergo strict inspection, and combine durability, precision, and stable performance. Their high quality is confirmed by experience in automotive, electrical engineering, machine building, and metallurgical industries.

What we offer distributors:

- Professional technical support

- Certificates & documentation

- Special purchase prices

- Convenient terms of cooperation

- Ongoing support

- Easy interaction

Contact us by email – become an NTE partner today!