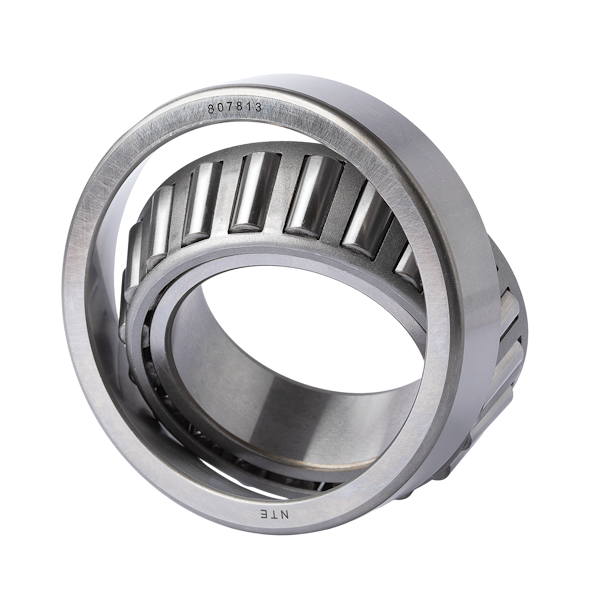

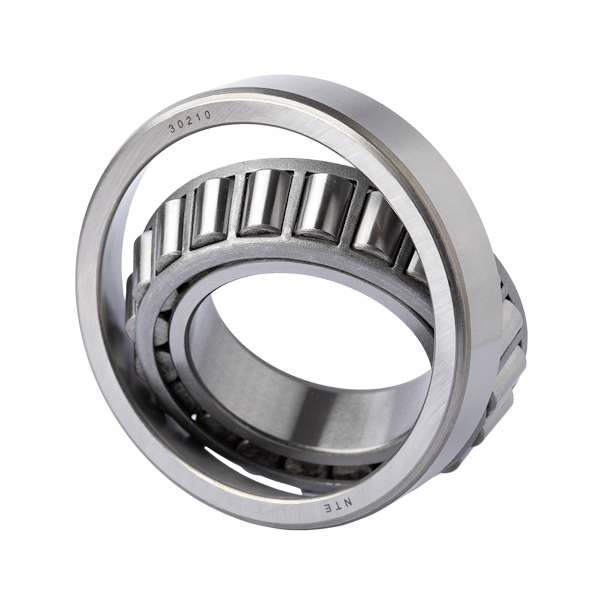

Tapered roller bearings

When a bearing is selected based on visual inspection or with inappropriate specifications, the load on assemblies can become critical, leading to bearing failure. This results in faster equipment wear and increased maintenance costs. To prevent this, NTE offers proven tapered roller bearings designed to accommodate combined radial and axial loads.

Size range

The brand’s range includes both standard and non-standard series, covering most industrial equipment needs:

- Bore diameter: from 15 to 850 mm

- Outside diameter: from 35 to 1360 mm

- Bearing width: from 11,75 to 114 mm

The size and type directly affect the tapered roller bearing price, while flexible selection helps optimize costs without paying for unnecessary characteristics.

The full-size range is available in the NTE technical catalogue.

Design and operating principle

NTE tapered roller bearings consist of two separate elements: an outer ring with a tapered raceway and an inner assembly that includes the inner ring, cage, and tapered rollers . The rollers are shaped like cones with truncated tops, ensuring close contact with the raceways and even load distribution.

A pressed steel cage keeps the rollers at an optimal distance, preventing friction and reducing noise. In most bearings, the contact angles range from 10° to 18° (7000 series). However, bearings with increased contact angles of 20° to 30° (27,000 series) are also produced and are capable of withstanding higher axial loads.

NTE offers to buy tapered roller bearings wholesale in open-type designs that ensure precise rotation and an optimal balance between quality and cost.

Technical specifications

The variety of series allows selecting a bearing for a specific unit, based on the calculated service life:

- Maximum rotational speed: up to 15,000 rpm. The bearing can withstand high loads without overheating.

- Operating temperature range: general-purpose models – up to +120°C, versions for higher temperatures are also available.

- Basic dynamic load rating: up to 1,220 kN depending on the inner diameter of the bearing.

For shaft location in both axial directions, single-row bearings are installed in pairs. To minimize shaft clearance and improve rotational accuracy, it is possible to order tapered roller bearings in matched pairs for paired installation.

Current values for speed, loads, and temperatures are shown in the NTE technical parameters table.

Industrial advantages

The most important advantage of tapered roller bearings from a technical point of view is their conical shape, enabling them not only to withstand combined radial and axial loads, but also providing:

- Ease of installation: the separable design enables quick mounting and dismounting, reducing downtime and minimizing installation errors.

- High load capacity: the tapered geometry and optimized roller arrangement allow the bearing to withstand significant loads.

- Versatility: the parts are suitable for most standard industrial applications and can be easily adapted to different industries, loads, and operating conditions.

- Durability: low friction and reduced vibration minimize wear on rollers and rings, extending service life.

NTE offers to buy tapered roller bearings, manufactured to ISO and AFBMA international standards, ensuring precise geometry and interchangeability of components. Metric bearings are standard for most industries, while inch-sized bearings remain relevant for specialized equipment.

Fields of application

Tapered roller bearings delivery is available for enterprises across various industries, including:

- Light industry: textile and food-processing equipment, packaging machinery.

- Automotive industry: wheel hubs, suspension systems, transmission assemblies.

- Agriculture: tractors, combines, seeders.

- Heavy industry: metallurgical equipment and rolling mills.

- Mining industry: crushers, conveyors, grinding machines.

Tapered roller bearings types

NTE offers bearings with different numbers of rows, allowing you to select the optimal solution for specific equipment:

- Single-row bearings – withstand radial and axial loads in one direction; used in standard assemblies where double support is not required.

- Double-row bearings – withstand loads in both directions due to a double roller system. This provides increased load capacity, saves space, and simplifies installation.

- Four-row bearings – due to their maximum load capacity, they are mainly used in heavy equipment.

Why choose NTE

- Stable supply – reduced waiting times.

- Quality assurance – certified products and multi-stage inspection.

- Flexible terms of cooperation – the option to buy bearings wholesale, discounts, and tailored offers.

- Extensive product range – multiple sizes and designs available.

Forget about frequent failures and repeated component replacements. NTE is your partner in equipment stability and durability. Take the first step – choose a trusted tapered roller bearings supplier in Ukraine and optimize your technical processes to achieve the best results!

Want to purchase?

Our official distributors

Take advantage of favorable terms and support - become an NTE distributor today!

We offer bearings compliant with international quality standards. NTE products are manufactured at certified facilities, undergo strict inspection, and combine durability, precision, and stable performance. Their high quality is confirmed by experience in automotive, electrical engineering, machine building, and metallurgical industries.

What we offer distributors:

- Professional technical support

- Certificates & documentation

- Special purchase prices

- Convenient terms of cooperation

- Ongoing support

- Easy interaction

Contact us by email – become an NTE partner today!